- Eager anticipation after eight-year hiatus

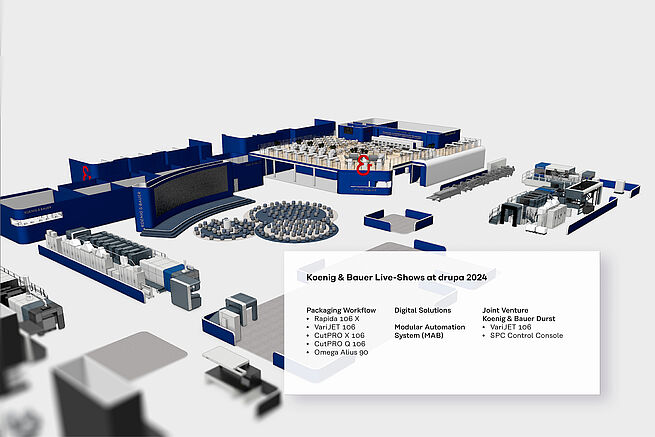

- Focus of the over 4,000 m² Koenig & Bauer stand (hall 16, A31) lies on the packaging market and digital solutions

- End-to-end packaging workflow with offset, digital and flexo printing and finishing

- Digital business models based on the core expertise of Koenig & Bauer

- Green Dot Award to honour innovative contributions to sustainable printing

© Koenig & Bauer

In a little more than a month, drupa will be opening its doors once more after an eight-year break. The motto “MORE” that hangs resplendent above the over 4,000 m2 stand reserved by Koenig & Bauer to present its innovations from 28th May to 7th June 2024 is as apt as it is concise. A special focus is to be placed on the packaging market and digital solutions. The three pillars of the Exceeding Print strategy – sustainability, digitalisation and modularity – define a common theme for all presentations and will offer visitors interesting insights into the diverse possibilities for raising print production to new levels of efficiency. Dr Andreas Pleßke, CEO Koenig & Bauer, has spoken to numerous industry experts over the past months, not least within the framework of drupa’s Print Promotion Industry Summit, and reports that everyone involved is eagerly awaiting drupa 2024. “As chairman of the drupa committee, I am looking forward to a spectacular trade fair with many highlights. As CEO of Koenig & Bauer, I look forward to presenting our latest innovations on the topics of digitalisation and sustainability to visitors.”

© Koenig & Bauer

Alongside the strategic core topics, all other areas of the comprehensive Koenig & Bauer product portfolio will be on show in Düsseldorf. The company is planning a combination of live events and hybrid shows.

Live first-hand experience: MORE efficiency thanks to individualised packaging workflows

“From pre-press to post-press, Koenig & Bauer products represent precision, performance and high-end solutions from a single supplier. Visitors to our stand will experience digital and analogue production lines that achieve breathtaking results with our workflow and digitalisation solutions,” says Ralf Sammeck, CDO Koenig & Bauer and CEO Koenig & Bauer Sheetfed.

Koenig & Bauer is bringing a firework display of technical innovations to Düsseldorf – demonstrating an end-to-end packaging workflow from pre-press, via printing and die-cutting to gluing of the folding cartons. All presses and machines presented at drupa – a Rapida 106 X, a VariJET 106, a CutPRO X 106 rotary die-cutter, a CutPRO Q 106 SB flat-bed die-cutter and an Omega Alius 90 folder-gluer – incorporate the very latest features. These features boost performance by at least 20 percent compared to the predecessor generations and once again set new benchmarks for folding carton production.

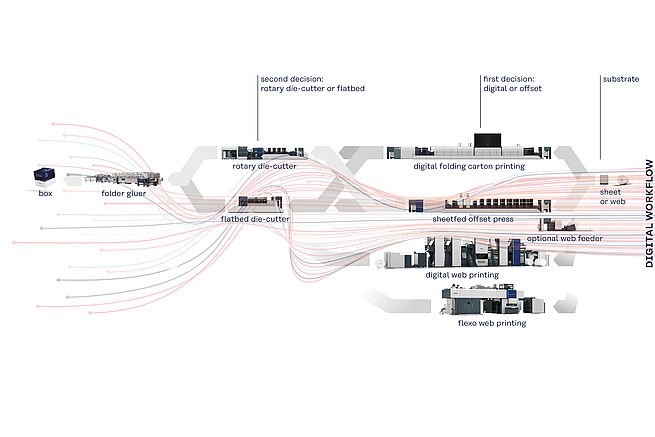

Koenig & Bauer users are offered a choice of different solutions, each tailored precisely to a particular business model:

With the Rapida sheetfed offset programme, the digital folding carton press VariJET 106 and flexo machines for the post-printing and further processing of corrugated board, it is possible to cover all typical production requirements, a broad spectrum of substrates and run lengths from one to one million copies.

For the post-press segment, Koenig & Bauer offers classic flat-bed die-cutters in medium and large formats, including models with extensive automation, alongside innovative rotary die-cutting solutions with up to four process units for embossing, creasing, die-cutting and stripping. With the AutoBlank system, furthermore, it is even possible to integrate blanking into an inline process.

The same diversity applies when it comes to folder-gluers: users can choose equipment to match their particular production requirements from four product families and a total of 16 different working widths. Koenig & Bauer can thus present the broadest portfolio of folder-gluers on the market. And all technical solutions are “made in Europe”.

© Koenig & Bauer

Navigating digital worlds: a new chapter for the printing industry

The printing industry, with its centuries-old heritage, has always been a fulcrum of human communication and creativity. Accordingly, Koenig & Bauer interprets the transition to the digital age not as a departure from traditional roots, but rather as an opportunity to perfect its own craft. The key task in this new chapter for the printing industry is to make use of digital progress, in order to improve the art of printing and to safeguard its relevance and vitality in the modern world.

Therefore, digital innovations play a major role in the packaging workflow implemented on the Koenig & Bauer stand and will here be presented to a broader public for the first time. “Full data transparency, innovative cloud and AI technologies, and new, ground-breaking business models stand at the focus of our digital strategy. At drupa, we want to show how even world-class machines can be raised to the next level with top-notch digital products,” says Sandra Wagner, Vice President Digitalisation Koenig & Bauer.

The best of both worlds: VariJET 106 combines inkjet and offset technology

Another highlight that can be seen in public for the first time is the VariJET 106 press developed by the joint venture Koenig & Bauer Durst. This digital press for folding carton printing combines the strengths of digital inkjet with the benefits of a classic offset process. It will naturally also be part of the packaging workflow on the Koenig & Bauer stand. The print samples produced on the press will illustrate a wide diversity of applications such as pharmaceutical, healthcare and cosmetics products, as well as food and beverage packaging.

Among the digital single-pass presses supplied by Koenig & Bauer Durst, the Delta SPC 130 is already well proven on the corrugated board market. Visitors to drupa will be offered a closer look at its SPC Control Console, and can learn how the Delta SPC 130 is integrated into the production environment on the basis of Durst workflow and analytics functionality.

“As a world-leading supplier of digital sheetfed presses, single-pass printing systems and software services for the folding carton and corrugated markets – and with two giants of the packaging and printing industry as partners – we see enormous potential for significant growth in the coming years, enabling us to support and accelerate the digital journey of our customers,” says Daniel Velema, Managing Director Koenig & Bauer Durst.

Koenig & Bauer to present its Green Dot Award at drupa

Demand-based production, reduced resource consumption and optimised print processes are top priorities for Koenig & Bauer. CEO Dr Andreas Pleßke predicts: “The subject will be a defining factor for the whole industry in future, because in our business sustainability goes hand in hand with lower costs.”

To sharpen customer awareness for sustainability issues and the associated benefits for their own production, and at the same time to shine a spotlight on the topic in general industry discourse, Koenig & Bauer has decided to present its Green Dot Award again this year – with a special ceremony on its fair stand at 1:00 pm on 31st May 2024. This award for outstanding sustainability achievements was created two years ago to honour visionary companies that have already made innovative contributions to sustainable printing in a special way.

From special applications to large formats: hybrid shows to exemplify the full Koenig & Bauer product portfolio

Alongside live demonstrations, Koenig & Bauer will be presenting its comprehensive product portfolio through a series of hybrid shows. Interested fair visitors from the segments for large-format and commercial printing, digital printing, corrugated board, flexo printing and post-press, as well as special applications such as glass and hollow container decoration, metal decorating and banknote printing, can in this way gain deeper insights into the endless diversity of the world of print.

As in medium format, the whole process chain for folding carton production can also be implemented for large formats with machines from Koenig & Bauer. A Rapida 145 sheetfed offset press, an Ipress 145 K PRO flat-bed die-cutter and an Omega Allpro 110 folder-gluer will demonstrate this in a show with live commentary. An excursion into half-format sheetfed offset is also planned, with a Rapida 76 press configured specifically for packaging printing.

In the field of labels, Koenig & Bauer will be showing a Rapida 106 X with reel-to-sheet feeder, cold foil module and further equipment details geared to label production. The printed labels will then be passed on to a CutPRO X 106 rotary die-cutter and a special blanking facility.

Further shows will focus on solution packages for industrial commercial printers. This means not only high-performance press technology, but also smart extras to support print companies in day-to-day production. Individual solutions can be configured to match the user’s specific business model and job structures, serving to boost efficiency and performance capabilities, ensure consistent quality management and improve production sustainability.

Highly automated corrugated board processing for more efficiency

Corrugated board processors can look forward to hybrid shows introducing the highly automated machines ChromaCUT X Pro and ChromaCUT High Tech 2S. On the ChromaCUT X Pro, a presettable die-cutter allows the makeready for a new die-cutting forme to be performed while current production is still running. The fully equipped and highly automated machine boasts a host of patented features and enables customers to increase their productivity by yet another notch.

The Chroma 2S technology is the most recent development from Koenig & Bauer Celmacch and is available for the Chroma High Tech and Chroma Smart series. It enables corrugated board processors to handle inside and outside printing in a single machine pass. This not only boosts efficiency, but also reduces production costs considerably.

RotaJET – High-volume digital inkjet web printing

Koenig & Bauer will be showing various ground-breaking applications for the RotaJET digital web press at drupa. The main focus will be placed on digital decor printing and high-volume inkjet packaging production. As a special highlight, the products interact directly with Koenig & Bauer’s digital AI solutions. At the same time, they will be protected on the basis of ValiPack solutions from Koenig & Bauer Banknote Solutions. Further folding carton products and high-volume inkjet applications are to be converted on the stand of BW Papersystems.

As the market leader in single-pass inkjet decor printing, Koenig & Bauer plans to showcase a range of decor applications on the stand. High-quality floor laminates with corporate branding or an AI-generated 18-metre decor without repeats raise digital decor printing to a new level.

CI flexo printing: compact and efficient solutions for the packaging sector

The drupa presentations for the field of CI flexo printing will focus on biodegradable film products for food packaging. The XD Pro combines a high degree of automation with simple operation, while the high-performance XG is available to handle high-volume production with optional flying sleeve changes (SSC). Ultimate efficiency is a particular hallmark, especially in folding carton and board packaging applications. The compact design of the CI flexo presses from Koenig & Bauer provides for fast job changeovers, maximum print quality and register accuracy even with the most difficult substrates.