- Digital innovations generated enthusiasm among visitors

- Presentation of the world's fastest medium-format sheetfed offset press

- Great interest in end-to-end solutions in packaging production

- Daily demonstrations and panel discussions on packaging workflow, digitalisation, commercial, CI flexo and digital printing

- Extraordinary order intake situation: around 250 million euros marketed since end of May 2024

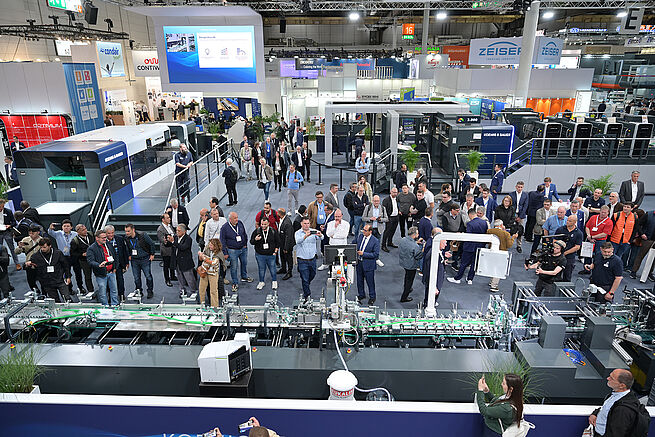

From 28 May to 7 June, Koenig & Bauer presented its broad product portfolio and numerous digital innovations at drupa, the world's largest and leading trade fair for printing technology in Düsseldorf. CEO Dr Andreas Pleßke, who is also Chairman of the drupa Committee, explains: “After eight years, both the exhibiting companies and the visitors have come to Düsseldorf with a great deal of commitment and enthusiasm. You can see how profoundly the entire industry has changed in recent years. Topics such as sustainability and digitalisation are key issues that visitors are increasingly demanding to be addressed and solutions found.”

Digital innovations become a crowd-puller

Pioneering digital innovations, presented in exciting live shows, prove to be real crowd-pullers. The digital intelligence Kyana came to life before the visitors' eyes and introduced herself personally to the interested audience as a virtual co-host. The myKyana portal presented itself as the centrepiece of the digital product world and impressively underlined how digitalisation can increase the efficiency, productivity and sustainability of companies. Kyana Assist caused quite a stir among the drupa visitors. The first AI chatbot in the printing industry enables Koenig & Bauer customers to interact directly with Kyana and receive direct support without waiting times.

In individual live demonstrations, visitors gained a detailed insight into the advantages of the comprehensive myKyana ecosystem directly on the stand. “At drupa, we showed how the combination of traditional printing and state-of-the-art AI and data-based technologies is shaping the future of the printing industry. The countless discussions with customers confirmed that digital productivity tools are becoming the decisive factor for investing in our technologies for printing and finishing,” emphasises Sandra Wagner, Vice President Digitalisation at Koenig & Bauer.

The new connected packaging solution FOLLOW attracted particular interest from brand owners and packaging manufacturers. The innovative platform transforms packaging into end-to-end, multimedia communication channels and takes the entire consumer experience to a new level. With augmented reality features and gamification elements, FOLLOW ensures a breathtaking product experience. In addition, the platform fulfils future regulations such as the Digital Product Passport and thus contributes to the sustainability and traceability of products.

Global interest in sheetfed offset

With a strong order intake, Koenig & Bauer has exceeded its own targets, especially in the sheetfed offset division. The majority of orders have come from China, Spain and Brazil. However, orders were also received from the DACH region, many other countries in Central Europe, Asia and North and South America. The orders relate to all format classes as well as the post-press area, which was on show at the drupa as part of an end-to-end packaging workflow. There was great interest in the innovative rotary die-cutters from the CutPRO X 106 series, flatbed die-cutters and folder-gluers.

The seven-colour Rapida 106 X with coater and extended delivery, which was presented on the stand with printing speeds of up to 22,000 sheets per hour, is the world's fastest medium-format sheetfed offset press. It was sold to the printing company I.G.B. - Innovative Graphic Boxes - in northern Italy during drupa. Once installed in Viggiù, the press will primarily produce pharmaceutical packaging.

All the postpress systems on show were also sold directly from the stand. Qualvis Print & Packaging, for example, will receive the Omega Alius 90 folder gluer, which the company from Leicester in the UK ordered in combination with a Rapida 106 with unique functionalities. A further Rapida 106 with seven inking units and double coater is already in production at Qualvis Print & Packaging.

The CutPRO Q 106 flatbed die-cutter will go to AM-PG Group, a commercial and security printer in Yerevan, Armenia. The company has been a Koenig & Bauer customer for more than 15 years and operates a medium-format Rapida press. The CutPRO X 106 rotary die-cutter, which can run at speeds of up to 16,000 sheets per hour, also attracted a lot of interest from international trade visitors. It was sold at the trade fair in various versions, including for die-cutting labels.

Koenig & Bauer Durst impressed with high quality and flexibility in digital printing

The VariJET 106 digital folding carton printing press from the Koenig & Bauer Durst joint venture was presented at a trade fair for the first time and impressed visitors during the product demonstrations with its high print quality and the flexibility of the entire configuration. In particular, the possibility of adding several coating and conventional printing units generated a great deal of enthusiasm among the trade fair visitors. Koenig & Bauer Durst, together with Highcon, demonstrated the possibilities of a fully digital production workflow from printing to finishing. The joint venture also confirmed two beta customers for the VariJET 106 and the planned installation of a VariJET at a European customer in July. With water-based digital printing in white for corrugated substrates in primary food packaging, there was also another industry first on show at the stand. Field tests on the Delta SPC 130 are planned for the second half of the year, with commercial installations to follow from the beginning of 2025.

Technological and sustainable innovations from the Digital & Webfed segment

An 18 metre long décor that stretched across the Koenig & Bauer stand immediately caught the eye of drupa visitors. Every centimetre of the AI-generated décor was unique and underlined the innovation and technology leadership of the Koenig & Bauer RotaJET in the field of digital decor printing. Furthermore, folding carton and top-liner products were at the centre of the RotaJET presentation. The products which combine high-volume digital packaging printing with the AR solution FOLLOW and the brand security solution ValiPACK deserved special interest. Koenig & Bauer had printed 15,000 TetraPaks on the RotaJET especially for drupa, which were available to visitors at the stand. The information areas for corrugated board and CI flexo printing were also very popular. The focus was on printing on bio-based and biodegradable substrates as well as the highly efficient ChromaCUT X Pro and Chroma HighTech 2S machines for printing on both sides of corrugated board.

High order intake at drupa: Confirmation of forecast for current financial year

“The great interest and the remarkable sales successes show that Koenig & Bauer has once again lived up to its claim of developing pioneering technologies for the printing industry for over 200 years,” emphasises CFO Dr Stephen Kimmich. Since the end of May 2024, Koenig & Bauer has marketed new orders worth €250m, including around €200m in legally binding orders. The order intake relates to all segments. The new orders were placed at and outside of drupa. The company confirms its forecast of achieving an operating EBIT margin and sales development at the previous year's stable level for the current financial year. The path already taken to achieve an EBIT margin of 6 to 7 percent on consolidated sales of € 1.5 billion by the 2026 financial year at the latest is also secured by the ‘Spotlight’ focus programme.

After eleven days on the Koenig & Bauer stand it is clear to see: drupa is a real trade fair. “The many exciting technical discussions with customers and experts from the industry make up the very special atmosphere at this trade fair,” says Ralf Sammeck, board member at Koenig & Bauer.