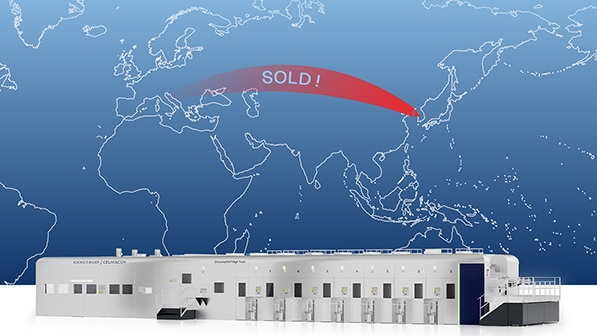

- Chroma series sold to Asia for the first time

- Full equipped ChromaCUT High Tech with four printing units

- New dryer technology improves performance with coated corrugated board

© Koenig & Bauer

The South Korean company Sambo Corrugated Board is investing in a ChromaCUT High Tech from Koenig & Bauer Celmacch. The Koenig & Bauer Celmacch rotary die cutter ordered by Sambo will be installed by the end of 2025.

“We had a clear idea about the new machine. Thanks to intensive and trusting discussions with Koenig & Bauer Celmacch, it quickly became clear to us that the ChromaCUT High Tech would meet our expectations 100 %. We also looked at many machines in Europe and were able to gain a very good insight into how well the machines from Koenig & Bauer produce.”

With a range of new technological features, the High Tech series has been continuously developed in recent years, making it to one of the best-selling machines on the market. „We are always implementing new ideas. Modern technologies and functions in combination with simple and intuitive operation characterise our machines“, explains Luca Celotti, Managing Director at Koenig & Bauer Celmacch.

New IR-dryer ensures higher performance with coated corrugated board

The ChromaCUT High Tech machine will be delivered with a working width of 2.4 m. With a whole range of advanced technologies and functions, the Chroma High Tech series is one of the most innovative and modern printing machines on the market. In addition to the possibility of pre-setting during production, it also offers an automatic changeover of anilox roll and reliable register control. Moreover, a new infrared dryer has been developed that further improves the performance with coated corrugated board. An innovative sensor control permanently regulates the dryer temperature and thus ensures increased energy efficiency. The direct drive technology and the belt-driven vacuum transport system enable outstanding print quality and high resolution. Thanks to the use of high-quality components, the machine meets very high customer demands for durability, reliability and maximum performance in the long term.

Quality, customer satisfaction, reliability

Founded in 1973, Sambo Corrugated is a family-owned company that operates five corrugated processing plants and one paper mill in South Korea. The country has a very advanced technological infrastructure and is home to top companies such as Samsung, LG, Kia, Hyundai, etc. Sambo has 800 employees (as of 2020). Since its establishment, under the motto of ‘Diligence and Sincerity’ ‘Accomplishment of Duties,’ and ‘Harmony and Unity’, all officers and employees have been united and endeavored for customer satisfaction with the best quality and service. Sambo has the optimal environment to deliver products quickly and accurately to their customers, whenever and wherever they want. In addition to the current five factories, Sambo has secured a 170,000 square meter site to build two more factories to achieve higher productivity. Sambo's main customers include Lotte, coupang (Korean Amazon) CJ, OB, Hite and more.