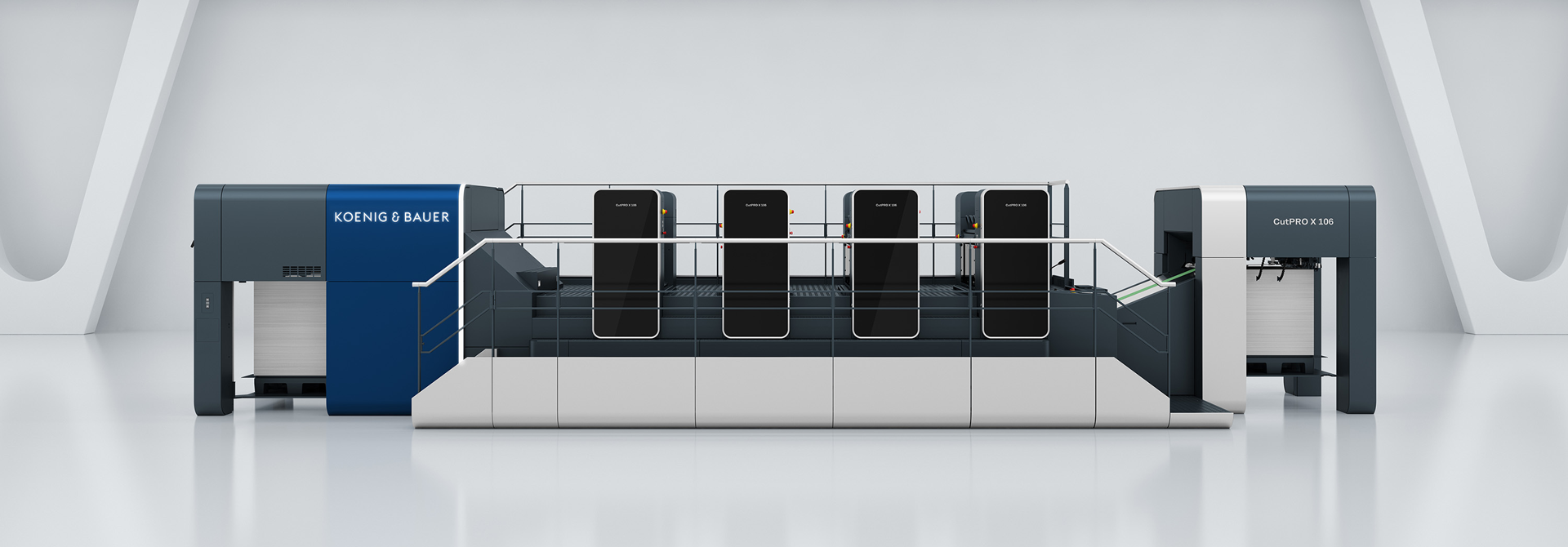

Maximum substrate flexibility with the CutPRO X 106

The CutPRO X 106 is a genuine all-rounder for applications in the fields of labels, commercial printing and packaging.

The production spectrum stretches from ultra-thin inmould films up to 0.6 mm board. That is made possible by the low-curvature sheet guiding concept of the CutPRO X platform, with double-size back cylinders and transfer drums. Aerodynamically optimised sheet guide plates lend additional reliability to sheet transport. From the DriveTronic feeder through to the delivery pile.

Depending on your planned application, you can choose from a range of special performance packages. They enable high-speed die-cutting production, also with sensitive substrates. Individually tailored, matched to particular substrates, and designed for outputs up to 15,000 sheets per hour.

Very fast makeready

Still on makeready or already cutting? The question becomes irrelevant on the CutPRO X 106. State-of-the-art automation modules provide for extremely short makeready times compared to flat-bed die-cutters. A complete job changeover, for example, is completed in no more than 15 minutes.

Job data can be transferred via an integrated USB port, or else presetting data are loaded via CIPLinkX or LogoTronic Professional.

Sheet separation and transport into the machine is fast and extremely precise – no problem with the high-performance feeder of the CutPRO X 106. Koenig & Bauer DriveTronic dedicated drive technology ensures absolute ease of operation and the fastest possible makeready.

A die-cutting forme change is completed in approx. 2 minutes. Tool-free and convenient, following the principle of automated forme changes on the coater of a sheetfed offset press. A laser sensor scans the die-cutting forme to enable automatic presetting of the forme thickness. This eliminates the time-consuming fine alignment of the die-cutting forme which is otherwise necessary on a flat-bed machine.

By the way, all job-specific machine settings can be saved for later recall. That saves time in case of repeat jobs!

Perfect die-cutting results

The heart of the die-cutting unit is a precision-ground magnetic cylinder running in play-free bearings. The true-running accuracy of this cylinder is +/- 5 µm. Permanent magnets ensure reliable fixing of the die-cutting forme.

An additional register pin system permits fast and precise forme positioning. Lateral, circumferential and diagonal register functions provide for fine adjustment relative to the sheet.

CNC-manufactured dies stand for absolute accuracy and minimum tolerances. They enable cutting of even the smallest radii and contours, which would not be possible with the steel rules of a flat-bed forme.

The ultimate precision of die-cutting is also supported by the exact pressure control between the forme and back cylinders. The pressure is set from the ErgoTronic operating panel in steps of 1 µm.