Koenig & Bauer's wide ranging sheetfed offset portfolio has a laser focused aim, and that is to offer you highly profitable solutions across the packaging, commercial and label segments. We offer the widest industry portfolio from B2 to large format. Across all format classes, high-performance Rapida presses set industry leading standards in terms of productivity, colour control, flexibility and efficiency. In large format and packaging printing Rapidas are already the established market leaders, and we have similar aims for the commercial and label segments. You, of course, are always trying to innovate, so we strive to offer unique solutions for print and sheet enhancement, game changing technical features and tailored configurations to meet your requirements. These have always been core strengths of Koenig & Bauer Sheetfed.

Sheetfed - products for packaging, label, commercial printing and for various finishing processesSheetfed Offset

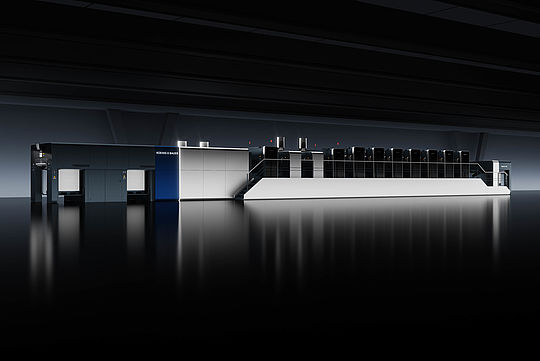

Now available.The New Dimension in Large Format

The time has come. The new generation of large-format sheetfed offset presses is here - for your success in the jumbo format. Can't wait to find out more?

Medium Format

Medium format is the largest industry sector, and that’s why we offer a wide range of machines to cater for every segment, every output volume requirement and every level of printed sheet complexity. All of our medium format machines are aimed at fitting your productivity needs therefore offering you maximum profitability. A high degree of tailored options allow you to specifically make it your machine, for your market.

Half Format

Industrialised print production for the B2 sector – specifically designed to offer all the benefits of our larger sized presses but in half format. The latest generation has recently been upgraded and redesigned to offer you even more benefits in your daily business. Our available options allow you to tailor the machine specifically for your needs, be it packaging, commercial, or label.

Digital sheetfed printing

With VariJET 106 you are ideally equipped to produce the packaging of the future. You can combine the best of conventional and digital print with a diversity of inline product refinement possibilities. As a modular system, the VariJET 106 can be configured exactly the way you require for your particular production needs.

Postpress

What makes your print products truly unique? The exceptional print and finishing quality is a major factor, of course. But original refinements and special haptic or visual impressions also catch the eye and stick in the mind. Treat your print products to a stylish finish – and take the lead on the market. Sophisticated coatings, brilliant cold foil applications and modern die-cutting options – we help you to shine with innovative Rapida technology. Choose between the rotary die cutter CutPRO X 106 and the flatbed die cutters CutPRO Q 106 SB - the new generation, Optima 106, Optima 106 K, Ipress 106 PRO, Ipress 106 K PRO, Ipress 145 PRO or Ipress 145 K PRO, as well as the folder gluers.

Quality measurement & control systems

To enable users to answer the ever higher quality demands and expectations of their customers, Rapida presses can be equipped with a diversity of quality measurement and control systems. These systems contribute to faster makeready, help to reduce waste, and ensure constant high quality in print production.

Workflow Solutions

Consistent digitalisation of your business and production processes is a decisive factor for the future viability of your company. Competent data handling and intelligent automation accelerate your processes and lend a sustainable boost to your flexibility and efficiency. Implement your vision of Print 4.0 with Koenig & Bauer Workflow Solutions.

- Optimus dash

- LogoTronic

- Job Optimiser

- Performance Analytics

This might also interest you