Five Years of Packaging Competence Center at Koenig & Bauer in Radebeul

End-to-end folding carton workflow in the Customer Experience Centre

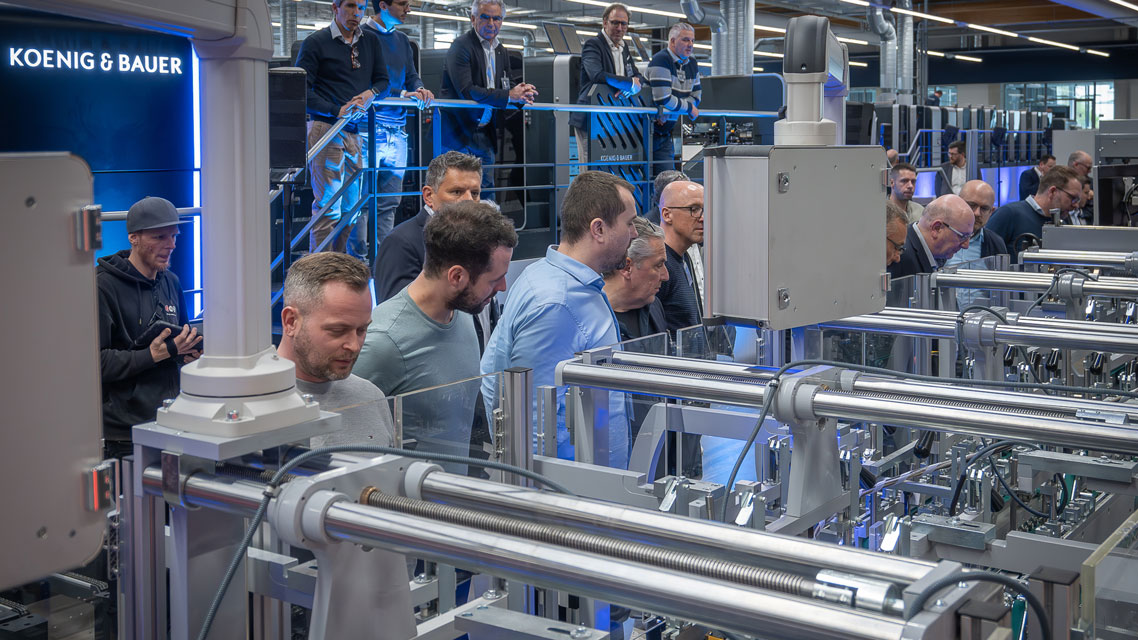

- Meeting point for operators and customers from around the world

- Second generation of machinery with modern technology in all format classes

- Innovative production processes including digital folding carton printing and rotary die-cutting

- Modern workflow solutions including AI and data-driven products

© Koenig & Bauer, Martin Dänhardt

In April, it will be exactly five years since Koenig & Bauer in Radebeul opened a new hall with more than 3,000 m² of demo and production space as an extension of its in-house Customer Experience Centre. The new building houses the Packaging Competence Center with several packaging lines from printing to die-cutting (flatbed and rotary die-cutting) and folding carton gluing. Workflow solutions for the packaging industry, end-to-end data management in all phases of production and AI-supported, data-based and digital business models that take the entire life cycle of printed products into account are also presented here.

At that time, an official opening in person was cancelled due to the Corona pandemic. In the years that followed, the Packaging Competence Center developed into an excellently utilised meeting point for packaging companies from all over the world.

© Koenig & Bauer, Martin Dänhardt

In addition to machine demonstrations, application tests and process engineering developments, the broadcasts as part of the virtual drupa 2021, for example, came from the new Packaging Competence Center – as did many live broadcasts of demos to all parts of the world. From the outset, the installed technology has mapped the end-to-end packaging workflow from pre-press to printing and die-cutting through to folding carton gluing.

© Koenig & Bauer, Martin Dänhardt

Current machine models ready for demonstration

The original technical equipment has been or is currently being replaced by the latest products. For example, a Rapida 76 has recently become available for printing demonstrations in the high-quality cardboard sector (pharmaceutical and luxury packaging). A CutPRO Q 106 flatbed die-cutter has been newly installed and an Ipress 106 SB is currently being set up. The Rapida 145 from the initial year has already left the hall and will be replaced by a new machine of the same series from May. In total, there will then be three packaging lines in three different format classes with the following technology available for application tests:

- Digital solutions: myKyana, VisuEnergy X, Kyana Data, Kyana Connect, Kyana Assist

- PrintFusion: end-to-end packaging workflow between pre-press and printing in collaboration with Hybrid Software

- Sheetfed offset: Rapida 76, Rapida 106 X, Rapida 145

- Digital folding carton printing: VariJET 106

- Die-cutting: CutPRO Q 106 and Ipress 106 SB flatbed die-cutters, CutPRO X 106 rotary die-cutter

- Folder gluing: Omega Allpro 110, Omega Allpro 70

© Koenig & Bauer, Martin Dänhardt

More than 5,000 users from all over the world and from all continents have already visited the Packaging Competence Center and extensively tested the technology in preparation for their own investments. On average, up to three printing demonstrations take place simultaneously on the seven available machines. In addition, there are parallel printing demonstrations in commercial and label printing in the Commercial and Label Competence Centres.

© Koenig & Bauer, Martin Dänhardt

Full utilisation of capacities

The Packaging Competence Center is also well booked for the future: An Open House with the theme “Expand Your Business Model” is planned for May, where all machines will be producing live. In addition, there are daily printing demonstrations for interested parties from all over the world. With its new building, the Customer Experience Center has developed into an important meeting point for the international printing industry.

© Koenig & Bauer, Martin Dänhardt

English

English

Deutsch

Deutsch