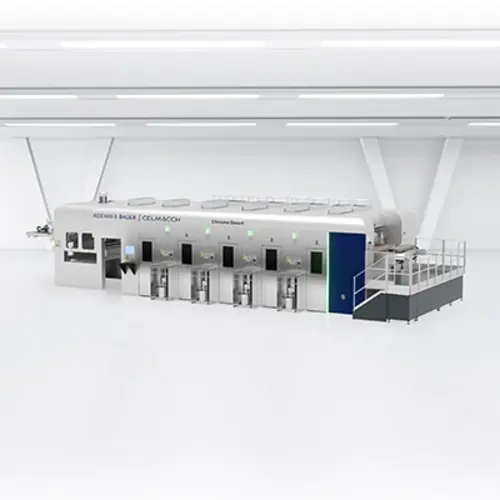

The Chroma X Pro has been designed for high-performance flexo post print in ultimate quality.

Flexo Post-Printing Presses

From Koenig & Bauer Celmacch

Chroma High TechFlexo Post-Printing Press for Corrugated Board

With numerous advanced technological features and functions, the Chroma High Tech is among the most innovative and state-of-the-art printers on the market.

Chroma SmartFlexo Post-Printing Press for Corrugated Board

Within our range of high definition flexo presses, Chroma Smart represents a perfect combination of innovation and functionality.

ChromaCUT X ProFlexo Post-Printing Press & Rotary Die-Cutter for Corrugated…

The high board line rotary die-cutter ChromaCUT X Pro – Experience transferred into state-of-the-art technology.

ChromaCUT High TechFlexo Post-Printing Press & Rotary Die-Cutter for Corrugated…

The ChromaCUT High Tech combines the advanced and well-proven printing technology of the ChromaPRINT with the highest precision of the rotary die-cutter.

Unlocking the Potential of Corrugated Packaging

With Flexo Post-Printing

Corrugated packaging plays a vital role in protecting and transporting goods, but it's also a powerful marketing tool. Flexo post-printing allows you to transform plain corrugated board into eye-catching packaging that enhances brand visibility and attracts consumers. From simple designs to complex graphics, flexo post-printing offers the versatility to create packaging that stands out on the shelf.

Flexo Post-Printing

A Versatile Process Used for a Wide Range of Corrugated Packaging Applications

- Retail packaging: Create visually appealing boxes and cartons that attract customers and enhance product presentation

- Shipping cartons: Print clear and informative labels, logos, and handling instructions on shipping cartons for efficient logistics

- Point-of-sale displays: Produce eye-catching displays that promote products and drive sales in retail environments

- Industrial packaging: Print durable and functional packaging for industrial goods, ensuring safe transport and storage

- E-Commerce packaging: Enhance the unboxing experience with custom-printed e-commerce packaging that reinforces brand identity

Our Flexo Post-Printing Presses Offer Several Key Advantages

For Corrugated Packaging Production

- High print quality: Achieve sharp text, vibrant colours and detailed images on a variety of corrugated substrates

- Cost-effectiveness: Flexo printing is a cost-effective process, especially for high-volume runs

- Fast turnaround times: Flexo presses offer high printing speeds, enabling quick turnaround times and meeting tight deadlines

- Versatility: Print on a wide range of corrugated board thicknesses and finishes

- Sustainability: Flexo printing can utilise water-based inks, reducing environmental impact

Why Choose Koenig & Bauer for Flexo Post-Printing?

- Decades of expertise: Koenig & Bauer has a long history of innovation in printing technology

- Customised solutions: We offer tailor-made flexo post-printing presses to meet your specific needs and production requirements

- Advanced technology: Our presses incorporate the latest advancements in flexo printing, ensuring optimal performance and efficiency

- Comprehensive support: We provide comprehensive support and service to ensure your presses operate at peak performance

Koenig & Bauer Celmacch

Your Partner in Corrugated Packaging

We understand the challenges and opportunities in the corrugated packaging market. Our corrugated post-printing presses are designed to deliver exceptional quality, productivity, and flexibility, helping you achieve your business goals.

Interested in Flexo Post-Printing?

Fields marked with a * are mandatory. You will receive an e-mail confirming your contact request after you have filled out this form.

English

English

Deutsch

Deutsch