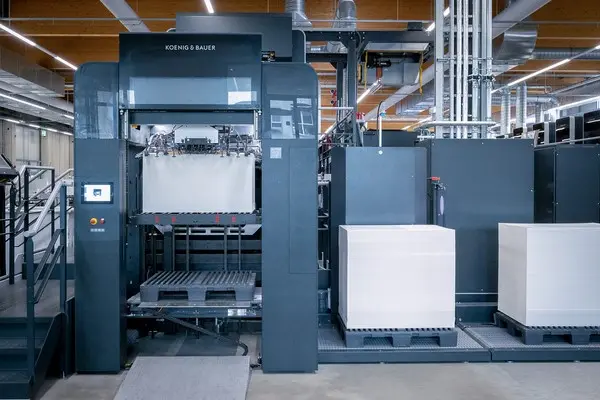

Complex offline foil application using a letter press machine or dedicated flexo printing unit is no longer necessary, because the cold foil modules from Koenig & Bauer enable you to apply such special-effect foils via two normal printing units of your sheetfed offset press.

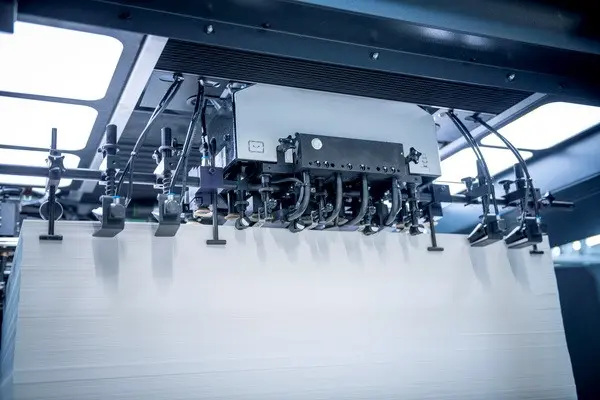

The first unit is used to apply an adhesive – via the ink duct and an offset plate in the same simple manner as an ink. The second unit then handles the actual foil application. To this end, the foil web is passed through the impression gap between blanket and impression cylinder, where it comes into contact with the substrate. Particles of aluminium from the metallised carrier are thereby transferred to the sheet in the areas to which adhesive was applied. Immediate inline overprinting with conventional or UV-reactive inks produces a dazzling array of metallic colours – all in perfect registration.

- All-over or partial foil finishing at up to 18,000 sheets/h

- Use of standard offset plates, rollers, solvents and blankets to apply the adhesive

- Fast and simple job changeovers

English

English

Deutsch

Deutsch