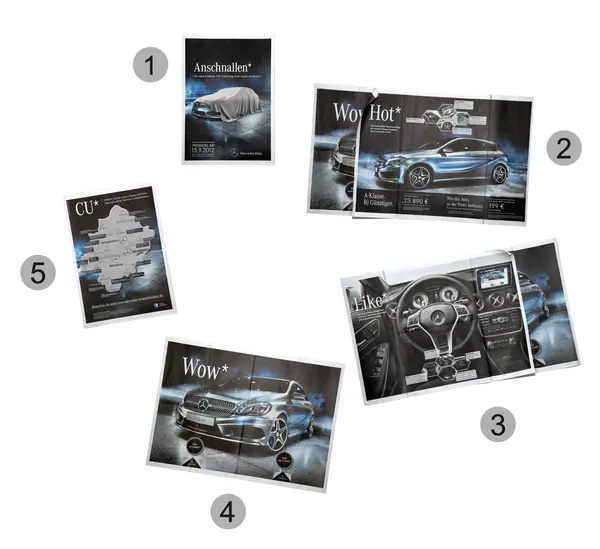

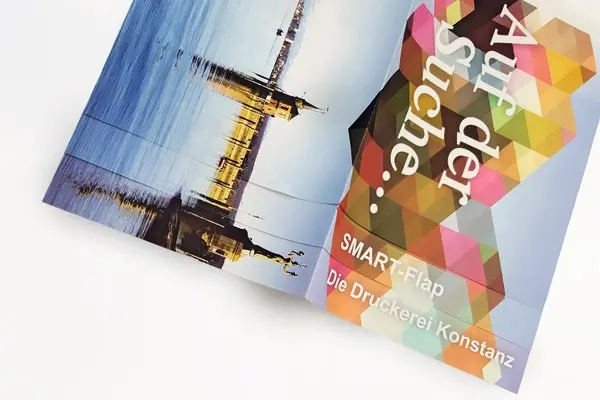

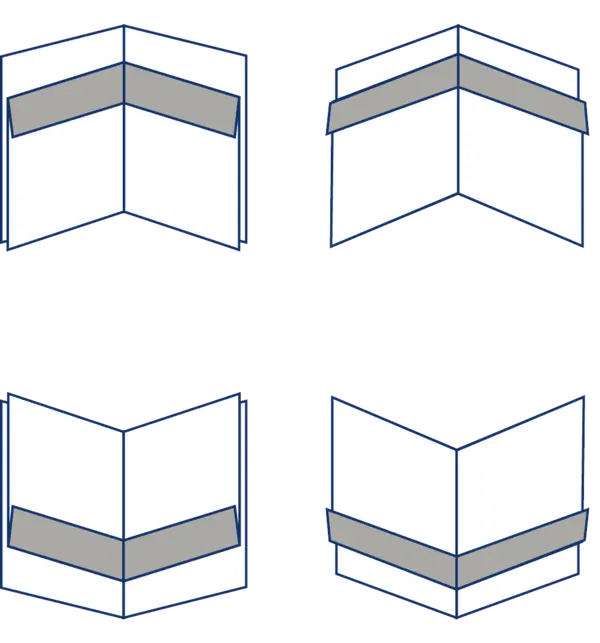

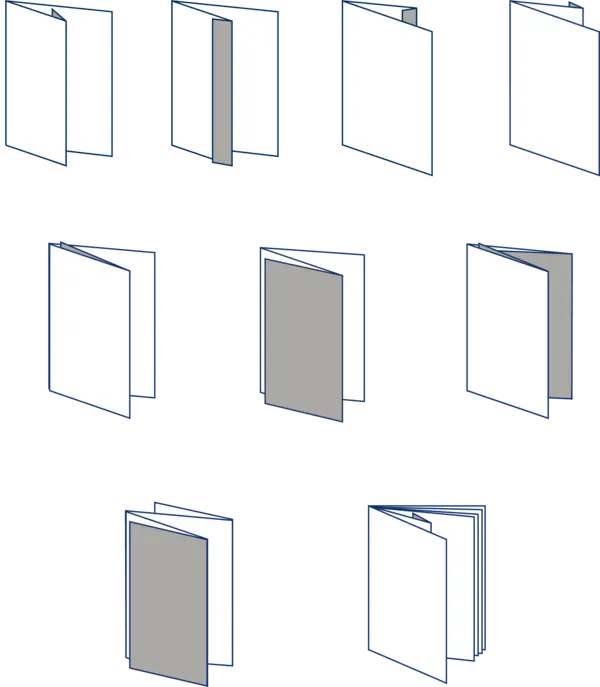

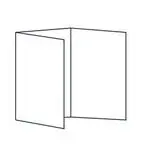

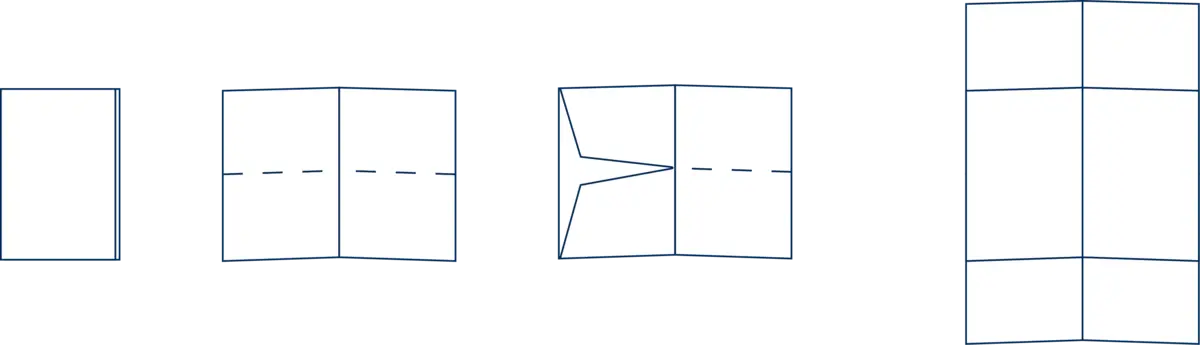

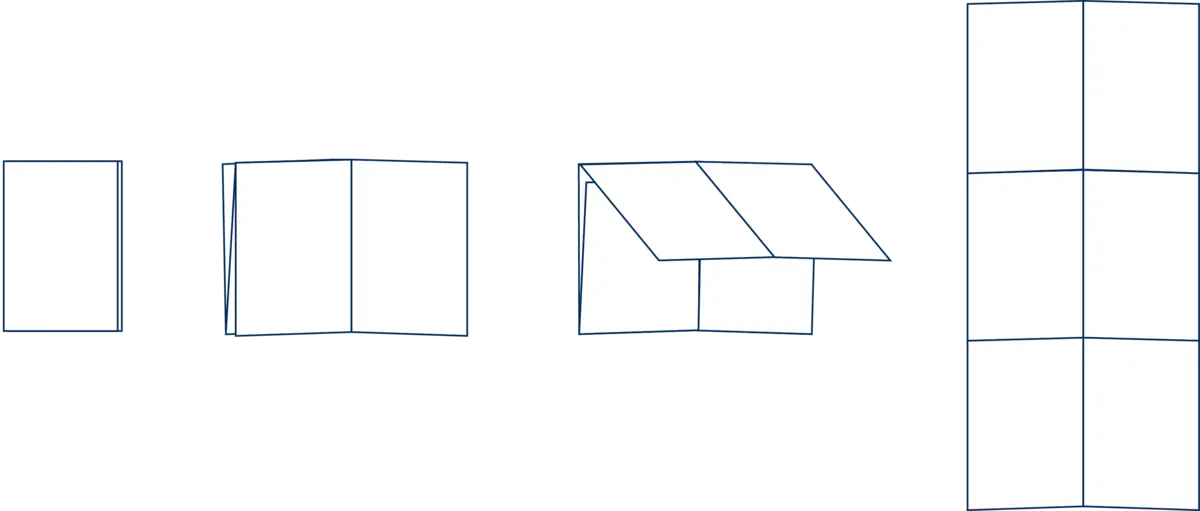

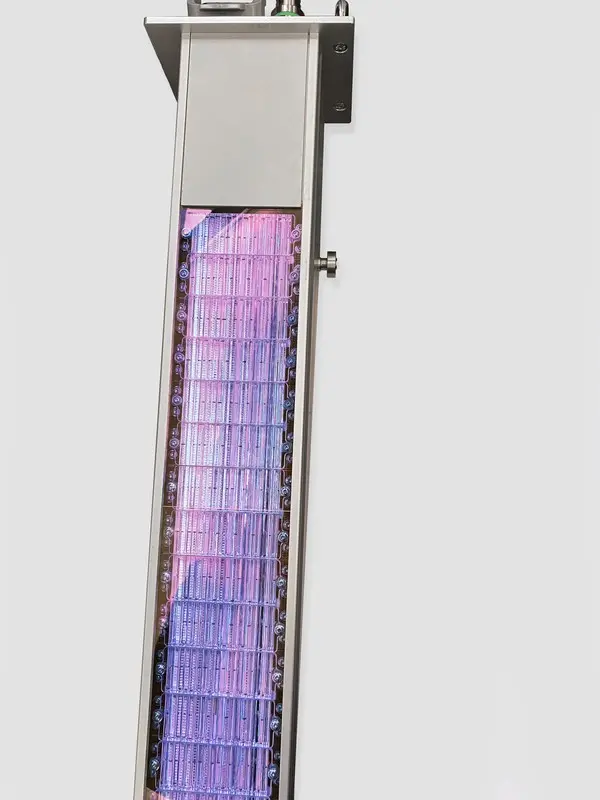

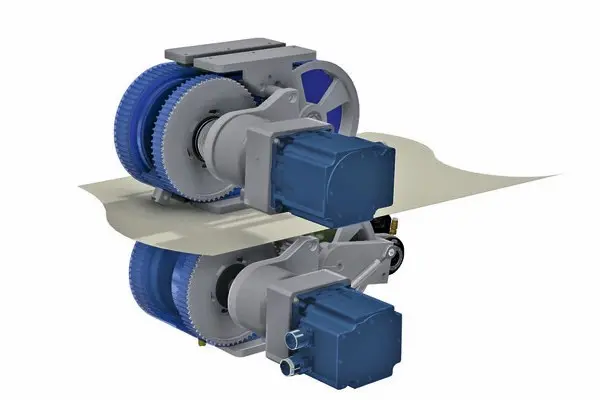

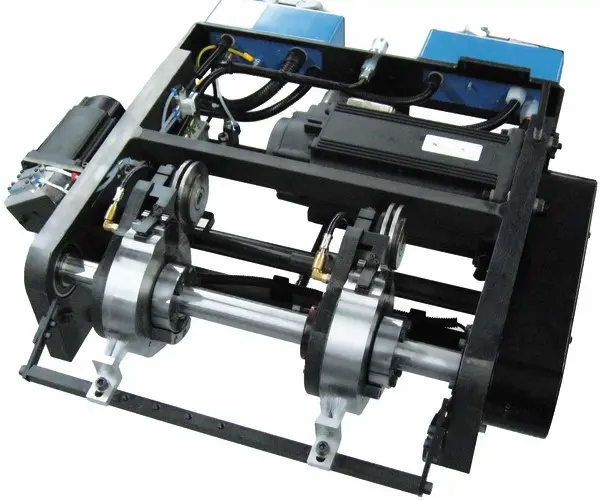

By creatively folding, gluing and perforating two webs to feature two “zips”, you have a product which can be opened up by readers to reveal 5 different advertisements.

The reader “discovers” the product being advertised step by step by opening the perforations. Physical more-intensive advertising engagement over a longer period leaves a lasting impression in readers’ minds. MultiView is compelling. Its eyecatching design engages readers and stands out above the crowd of classic advertising formats.

English

English

Deutsch

Deutsch