- Broadest product range in the industry

- Key supplier to the global media industry

- More than 200 years of printing innovation

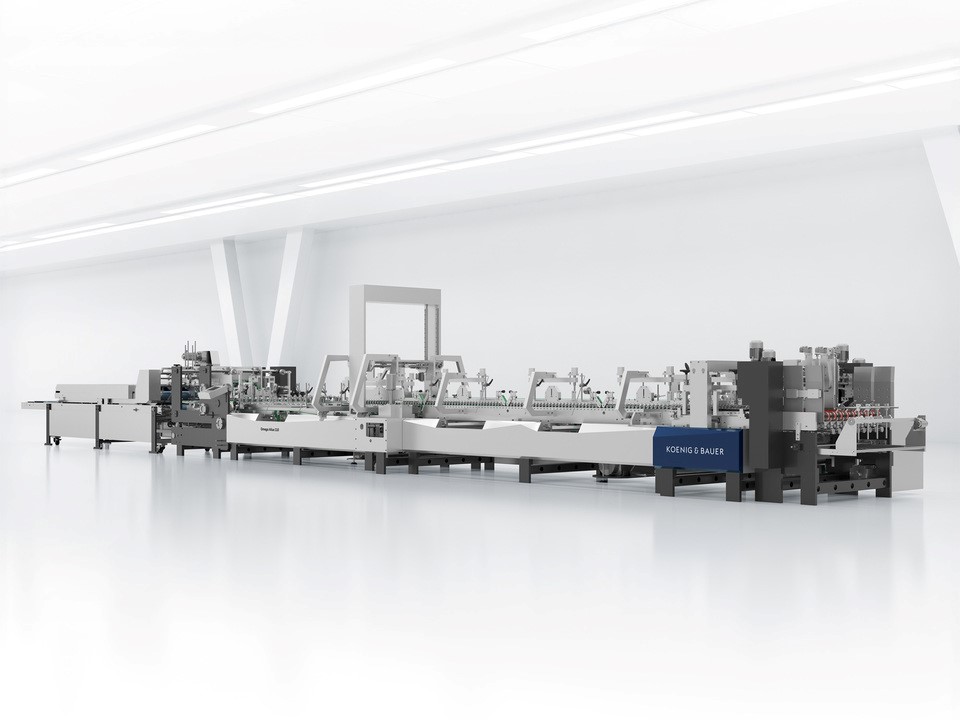

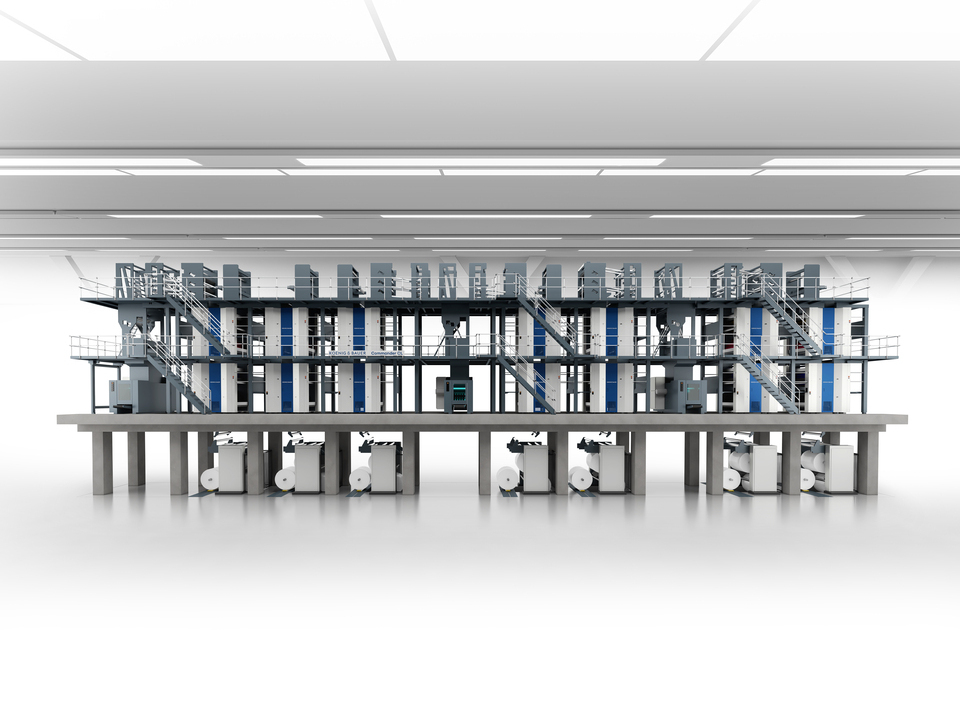

- Development and manufacture of technologically innovative yet cost-effective printing systems and peripherals

Annual Report 2024

ChanGe | ChanCe

Change is a constant in our company’s history. For over 200 years, we have been facing new challenges, driving innovation and seizing opportunities. Yet, never before have change and opportunities been so closely linked as they are today.

Our actions are therefore guided by the motto Chance & Change.

Our Products – Sorted by Technology

Whatever kind of printing press you're after, we've got the right solution and technology for you. We offer a wide range of options to make sure you find the perfect machine for your specific needs.

Vision & Protection

The Next Level of Authentication

With our next-level authentication solutions, we help you to develop a new understanding of the dimensions of security. Improve the customer experience of your packaging with us, protect your products or link physical objects with the digital world. Our authentication solutions go beyond an optical quality check and together we will develop your concept to maximise the security of your products.

English

English

Deutsch

Deutsch